All threaded holes in the block and cylinder head should cleaned and tapped with a thread chaser. All bolts being installed should be lubed with a light oil or anti-seize on the bolt threads before assembly.

The base mount must first be installed on the block. Position the base mount so that the shorter side is in the direction you would like to shift the engine. If you want to shift the engine forward, place the shorter side of the base towards the front of the engine.

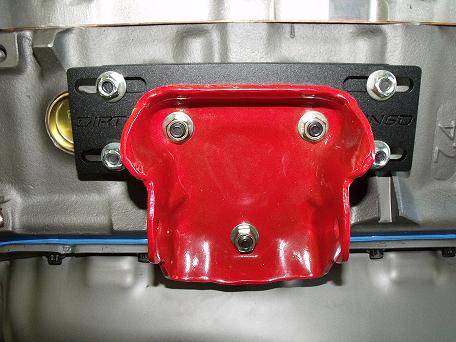

This is a drivers side mount. Test fit all bolts to verify they seat properly when tightened. Some blocks are not chamfered deep enough in the engine mounting holes, this will not allow the bolts to seat and tighten properly. You can either chamfer these holes deeper, or we supply thin 3/8 washers to place under the base plate to slightly space the base of the Mis-Fit mount to allow the bolts to seat when torqued. Place lock-tight on the counter sunk bolts and torque into the block 28 ft. lbs. Next, place your engine mount or clam shell onto the top plate. Use the provided 3/8 counter sunk bolts. Put a drop of oil on the threads of each bolt. The nuts may bind if you do not lube the threads. Place one washer and a lock nut on each bolt and torque to 28 ft. lbs.

Place the top plate with your engine mount installed onto the base plate that is on the engine. Put a drop of oil on the threads of each stud. The nuts may bind if you do not lube the threads. Place one washer and lock nut on each stud. Tighten nuts by hand, do not torque them down yet.

If the transmission mount is loose this will allow you to slide the engine back and forth into the desired position. Once you have engine positioned, tighten the lock nuts to 28 ft. lbs.